June 11, 2021

It is easy to get confused about what brushless drill is simply because not many people are aware of what a brushless drill is all about. Moreover, not many people understand the different features of a drill and how drill functions. Hence, to understand completely what a brushless drill is, one must understand how the earlier drills and power tools were made.

Brusless Drill VS Brushed Drill

Earlier drills generally came with a motor system consisting of four essential parts, namely: carbon brushes, armature, magnets, and commutator. These specific parts work together to create the necessary drilling motion that enables the machine to operate.

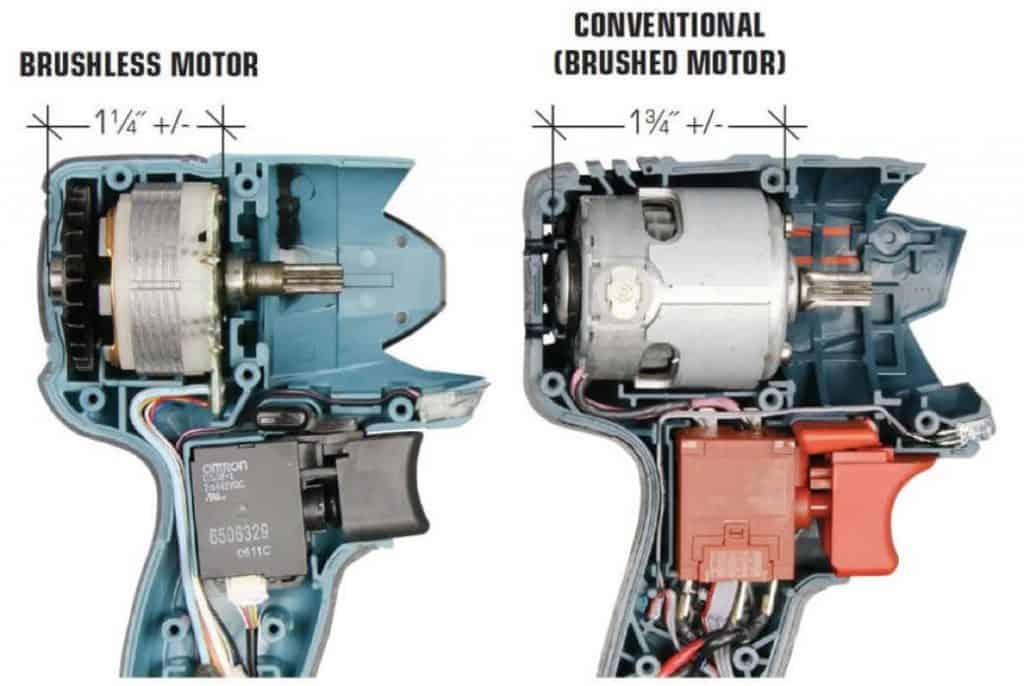

Most conventional brushed drills have carbon brushes. On the other hand, the brushless drills obviously no longer have the carbon brush, and for this reason, have different parts than the traditional drills. They also have eliminated the commutator; hence, they are basically differently designed than the conventional drills. Moreover, they are the latest development in power tools, and these brushless drills work more efficiently as compared to the traditional brushed drills.

You may still be confused as to what the differences are between the traditional and the brushless drills. Hence, an in-depth understanding of the functions and works of both these drills can further clarify the difference between these two types of drills.

What Is the Brushless DC Electric Motor?

The evolution of brushless DC electric motors became possible when the solid state’s electronics were developed in the latter half of the 20th century. Also known as Synchronous DC motors, these motors are run by DC electricity. These motors usually produce torque by simply interchanging the rotor’s rotating magnets’ polarity and the stationary magnets of the stator. Either one of these magnets or most of them is electromagnets. These magnets are usually made of spools of wire rolled around an iron core. As the electric current moves through the wires, it creates a magnetic field that runs the motor. The motor controller, on the other hand, converts DC into AC.

The brushless motor’s design is definitely well-thought of and more complicated than the brushed motors. The main difference, however, in their designs is on how the power is transferred to the spinning rotor from the outside motor. The good thing about the brushless motor is that it is equipped with an electric sensor that readily detects the rotor’s specific angle and the control switches that control the current that flows through the windings.

The Brushless motor system is comparable to the permanent magnet synchronous motor (PMSM). Additionally, the brushless motor system offers various advantages, and despite the fact that it is more expensive than the brush-styled motor, it is increasingly becoming more popular than the brush-style motor system.

How Does the Brushless Motors Work?

Since the brushless motor doesn’t have the commutator and the brushes, its design has been radically altered as compared to the brush motor. The primary difference is concerning the locations of the windings and magnets since the locations of the two have been reversed. The magnets are now located on the conventional motor shaft. The copper windings likewise of the armature are set fixedly, surrounding the shaft. A small circuit board also coordinates the way the energy is delivered to the windings. Due to the direct communication between the electronics and the stationary windings, the brushless can readily adjust itself accordingly as if it is a smart tool.

The power that is needed to drill through a material is commensurate to the amount of power required to bore a hole into the material. Hence, if you are boring through soft wood, the amount of power that is used is less; while if you are boring through a harder tool, the brushless tool will readily adjust the power inflow based on the hardness of the material being drilled. On the other hand, the brush motor always runs consistently whether it is drilling through a softer material or a harder material.

Moreover, brushless motors are powerful because their copper windings are situated outside the motor configuration, allowing for larger windings. Aside from these advantages, the brushless motors also eliminate the typical voltage drop and friction created by the dragging force against the commutator. This friction generally results in energy loss when operating the tool.

Is the Brushless Motor Better than the Brush Motor?

Other factors set the brushless motors above the traditional motors. First, the brushless motors can sense things better compared to the traditional drills. The traditional drills can’t distinguish between soft and hard materials. Brushless motors, however, are considered smart because they treat materials differently. They can differentiate between soft and hard materials.

Brushless motors rely heavily on a circuit board. This circuit board relays the signal to the armature from the battery. This is the determining difference between the traditional and the brushless motors. Through this circuit board, the brushless motors can complete any task using the minimum power needed to complete the given job. This enables the equipment to prolong its battery. Furthermore, brushless motors are known to be stronger and more powerful compared to the brush motors. For this reason, many contractors opt for the brushless despite their being expensive.

Conclusion

Although many benefits come with the use of brushless motors, some people still find it hard to buy brushless motors simply because they are costly. These kinds of high-end brushless drills are surely more suitable for professionals who need a power tool that is reliable and heavy-duty. Moreover, if you are on a tight budget, you would surely think twice before shelling out your hard-earned money for this tool.

The brushless drill is around 30% more expensive than the traditional drills, and as such, not many drill users opt for it. Furthermore, not many manufacturers dare to join the bandwagon of producing brushless motors. Hence, there are not many manufacturers who produce brushless drills. The upside, however, is that the brushless motors will further evolve as time goes by. As more manufacturers in the future would engage in the development of brush motors, more power drill tools will be made available to the common users of drilling tools.