June 13, 2021

There are many types of electrodes. But one of the most popular electrodes for beginners is the E6013. As you can see, electrodes are defined and characterized by four numbers. The very first two numbers “60” stand for its tensile strength which means the E6013’s tensile strength is up to 59,700 pounds per inch or almost 60,000 pounds per inch and its yield strength is 67,700 psi.

The third number of “1“, however, indicates that you can use these welding electrodes in all four positions of vertical, horizontal, flat, and overhead.

The last number “3” refers to the type of slag, flux composition, and power supply used for this electrode. The last digit indicates explicitly the following: if it is 0, it means DCRP. If it is 1, it means you can use either DC or AC Reverse Polarity. If it is 2, it means you can use DC or AC straight polarity. If it is 3, it means you can use DC or AC straight or reverse polarity.

Uses and Applications of 6013 Rod

The E6013 is designed for medium to light penetration welding. It is used for welding carbon steel and is also used for welding any type of polarity. As mentioned above, it is very popular for beginners because it readily provides a stable arc that is fit for welding poor fitting joints. It is also used for welding mild steels, some low allow steels, and galvanized steels. Its characteristic spray-type arc is very forceful and results in deep penetrations.

Moreover, you can easily remove the slag that it produces. The typical applications of the E6013 include welding sheet metals, vehicles, ship repair and building, and welding of overworked and overly worn-out mild steel surfaces. It can also be used in general and light fabrications.

You can use this rod for filling on multi-pass welds wherein you need to put on layer after layer to create a weld. The E6013 can also provide quality weld even though it produces shallow penetration by simply bonding with the metal that lays underneath it.

The E6013 is often preferred by beginners due to its excellent arc stability, making it suitable for weak fitting joints. Moreover, it leaves a smooth, pleasant-looking finish which, along with its arc stability, makes it convenient when working with uneven or short welds requiring positional adjustment. It is suitable for work on carbon steel and can be used for welding with any polarity.

Frequently used for:

- Welding of vehicles

- Shipbuilding and repair

- Excessively machined and damaged mild steel

- Thin sheet metal welding

- Other general light fabrication

Characteristics of E6013

E6013 is usually described as the “beginner’s rod, “sheet metal rod,” or even “easy rod.” These appendages to the E6013 may be indicative of its benefits. But you can also view these appendages negatively.

Although western people are distrustful of the E6013, it is however very popular among Europeans and Asians, especially, for purposes of doing a root pass welds. Moreover, Asians and Europeans seem to make the E6013 their choice when it comes to root pass.

The E6013 appears to have its merit for it leaves behind a smooth inside root. After a bit of trial and error, you would surely discover that the E6013 can be easily kept from overly reinforcing the root.

E6013 is characterized by easy flow nature, and this characteristic appears to work against it in the case of root pass. Contrariwise, however, it is not always the case, for this characteristic lets and prods the welder to move a bit quicker. Moreover, its backside slag formation in its weld is brighter and cleaner, indicative of less oxidation. This is surely a desirable quality when doing a root pass weld, especially, in pressurized situations.

The American welders may shy away from favoring the 6013 because of their biased view of this electrode; but a year from now, they may rethink their view about 6013. If you are a serious professional welder, however, you should not shy away from considering this aspect of 6013.

Results of Welding with E6013 Rod

The E6013 welding rod is a multi-purpose rod suitable for welding of mild steel, galvanized steel, and some low alloy steels. Although its coating generates a very stable, forceful spray-like arc, this electrode is not as deep penetrating as the E6011 which can penetrate thick or unclean material. Instead, the E6013 provides a light to medium penetration more fit for thinner steel, melding the metal together at a shorter distance below the surface between the electrode and the base metal.

The slag produced is thin and easy to clean up.

Polarity & Settings

The 6013 electrodes can be used with AC or DC (either straight or reverse polarity) in any position. It can weld mild steel to medium steel. However, there are some positive and negative reviews about the E6013. It has a thicker coating, for example, that does not spatter. Moreover, it can be used either with DC or AC polarity.

Pros & Cons

If viewed positively, we can say that the E6013 is very popular because it is easy to use and easy to master. On the downside, we can consider these appendages negatively as indicating that the E6013 is of less quality than those of the popular electrodes like the E6010 or E6011.

On the downside, the E6013 is viewed negatively because it leaves massive slag formation, and compared to the E6010, it is relatively shallow in penetration if you don’t know how to use it properly. If you know how to use it properly, you can inevitably produce high-quality welds, although these welds are not comparable to those of the E7018. Although it is not comparable to the E6010 or E7018 when it comes to the depth of penetration it produces, it inevitably can produce good weld, and it puts down a large amount of metal quickly and without difficulty. Furthermore, you would need an advanced rod angle and a tight arc to keep the slag from readily rolling right in front of your weld.

How To Weld With E6013 Rod?

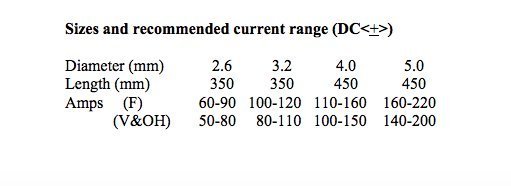

The primary thing that you must consider when using the E6013 is not to forget to adjust the settings of the amperage based on the E6013 size that would be used for welding the base metal that you are using. Moreover, you should clean the metal that you intend to weld using a wire brush for you to get the best possible penetration. Then, you can proceed with striking your arc by merely scratching the rod on the metal base once you decide to start the welding process.

A good view of what you are welding is a must. Hence, you should position yourself in such a way that you could see the electrode’s end as well as the arc that is produced. You should maintain your body in such a position while keeping your head away from the smoke that it creates. Use a 10 to 15 degrees angle position towards the travel direction to lead the electrode’s bottom. Lastly, you should follow the favorite technique of moving the electrode using a slightly circular movement or slightly whipping motion to produce good welding results.